Call or Write to: Church Bell Ministry -

Ph 423 926 3685

Cell: 423 747 0585 Email:

davessmith1001@gmail.com

We are Back! Changed Web Hosting suppliers. Uhg!

We

are sorry for any inconvenience.

Welcome

to the Church

Bell Ministry Website

Does your Church Have a Church Bell Ministry? What is that? A Church Bell Ministry

is one that utilizes the bell(s)

to witness to the community that God

Lives Here! The bell is an

outward invitation to the church whether it is heard by a church member or a

passerby.

Your Church Bell

Ministry provides your church the

recognition it deserves and praises GOD

every time it rings. Vintage

church bells were designed and manufactured for their pleasant

sound qualities, so why not show off a little! Look WHO we are showing off!

Church Bell Ministry

on a regular schedule once again in

To

provide an automated ringer system that is affordable for ALL churches.

Start Your Church Bell Ministry with a Programmable Church

Let

your church’s bell synchronize your community with the exact time (within one

second

of NIST time) and celebrate our Lord

with a familiar American sound!

Your

Bell can draw attention to the Lord and your church during the daytime

using

the TOD Clock Chime, even when no one is

there.

The Programmable Church Bell Ringer

System includes a Remote Solenoid to pull the bell’s clapper

against the bell to preserves the original tone of the bell. The “10 Pounder” Solenoid is used for bells 15” diameter and under. The “20 Pounder” Solenoid is employed for most bells and the “40

Pounder” is available for very large bells. These values are the rated force of each

solenoid.

The PCBR Hardware System

Features: The PCBR’s Controller is a Rabbit Semi 2000

Embedded Computer System. TOD Clock never needs setting with

built in atomic clock radio receiver. 2 line 16 character display LCD display

prompts all programming steps. Battery Backup retains TOD and flash

memory saves your user settings. World

Supplier of Affordable Church

The PCBR-I Kit is now available with an international option

which operates from 230vac!!!!!!

The Programmable Church Bell Ringer Plus’s User

Manual helps make

the system kit simple to install.

A PCBR

System

Wiring Diagram is available by clicking on this

link.

The

PCBR – International System Wiring Diagram is

available too!

The PCBR Plus box programs easily with

the two menu driven front panel pushbuttons and the 2 line LCD display.

The Church Bell Ministry is your supplier for D

I Y Church Bell Automation Equipment!

Simple mechanical design

provides years of reliable maintenance free service!!!

PCBR Plus and the 3 Bell PCBR Plus Kits

are available with an Atomic Clock Radio Receiver !

Because of customer feedback the

Programmable Church Bell Ringer is now available with an integrated Atomic

Clock Radio Receiver that automates

setting the clock, changing the clock at Daylight Savings Time and provides

time accuracy that is regularly

updated from the NIST Transmitter located near

How does that work? What does WWVB mean? http://tf.nist.gov/stations/wwvb.htm

State of the art electronics provides many

ring pattern and bell size options !!!

What’s in the box ? Put it this way – it’s

a lot more than just a timer.

The front side of the circuit board has the

LCD The rear side or component

side has the Rabbit 2020,

display, pushbuttons, battery, beeper and

fuse. the C-Max CMMC-8 Atomic

Clock Radio and other parts.

Think of the PCBR Box as an alarm

clock, except that it operates on a weekly schedule.

With the PCBR Plus Box – Set your

weekly ring schedule, select TOD Chime and forget it!

The PCBR Controllers are housed in a die cast aluminum enclosure with a

dark hammer tone

painted finish. Very Nice!

Einstein once s

Shown

below are the three locomotives that provide the clapper strike to match any

bell.

The 10 Pounder pulls the clapper with a 10 pound force. For 15” and smaller bells.

The 20 Pounder pulls the clapper with a 20 pound force. For 18” and up that pass the

one finger pull test. With the

bell tilted, if one finger will flip the clapper into the

side of the bell for a solid ring, then this is the correct solenoid for

your bell.

The 40 Pounder pulls the clapper with a 40 pound force. For very large bells. With the

bell tilted, if two fingers are required to flip the clapper into the

side of the bell for a

solid ring, then the 40 Pounder is the correct double solenoid for your

large bell.

PCBR

Software Features: Six Programmable Weekly Ring Times that announce each service by ringing for 1 minute

> Chimes on the hour from

> Chime at

>

> Angelus Ring Only

> TOD Chime and Angelus

Ring > No TOD Chime and Angelus Ring Clapper Solenoid active

(30, 60, 90 and 150 mSec) Bell Delay Time (1.5, 2.0, 2.5 and

3.0 Sec) Selectable ring pattern (single or twin ring) Manual Remote Pushbutton

rings the bell too Selectable ring pattern (single ring,

twin Ring, 25 ring peal, Angelus Ring and a Funeral Toll Ring) Call

or Write to: Church Bell Ministry Dave Smith 37659 Ph 423 926 3685 Cell: 423 747 0585 Email:

Six Optional Time of Day Clock Chimes

The Church Bell Ministry

is your supplier for DYI Church Bell Automation Equipment!

The Church Bell Ministry

offers a cost effective ringing solution for Catholic Three Bell Towers.

The Three Bell PCBR

Box provides the ring features below and all in one PCBR Box. Cool!

Small

Medium

three strikes, pause,

three strikes, pause, three strikes, pause, nine strikes.

Large

every 10 seconds for 5 minutes.

All Three Bells

–

The Wedding Toll provides a showering of all three bells in a pseudo random

ring pattern for one minute.

3 ·

3 Manual Push Buttons and Wire (0ne for each bell) ·

3 ·

Three ·

Clapper and Installation Hardware ·

3 Clapper Linkage Solenoid Sets (1 w/ Double Solenoid) ·

Installation and User’s Manual (rear of photo)

All three bells offer six

weekly ringtimes, with a selectable single or double ring pattern. (Ding or Ding – Dong)

Time of Day Clock Chime (

Three Manual Pushbuttons (1

for each bell) for ring operations with five selectable ring functions.

The Three Bell PCBR Box

is available as standard or Three Bell PCBR PLUS Box with the Atomic Clock Radio

Receiver.

The 3

The 3 Bell

Wedding Toll makes for a joyous celebration.

Click for a Wedding

Toll video from St. Mary’s in

The 3 Bell

PCBR Plus User’s Manual can be downloaded here!

A 3 Bell Ring

Schedule Form is available for download:

3 Bell Ring Schedule Form

Note: If the solenoid

hammers on your bell(s) are intact, the PCBR Box and an external solid state relay

(OPTO 22 P/N

240A25) or contactor (EATON

P/N C25BNB225A) with 120vac coil provides a cost effective replacement

controller!

(The cost of the Solenoid(s)/Linkage,

Bell Mounting Kit is excluded in the price)

(

The Programmable

Church Bell Ringer operates from 105 -130 vac power. The cost to operate is only pennies per year.

Speaking of cost – The PCBR System Kit (includes everything except the

2x4s) sells for $695 for the standard system kit.

- The PCBR-I System Kit (same as above but 230vac) sells for $745 for the standard system kit.

- The PCBR Plus System Kit with Atomic

Clock Radio sells for $895.

- The Three Bell PCBR System Kit sells for $1395. The Three Bell Kits include three sets of

solenoids

and linkage including a

Double Solenoid option for the Large or “DeProfundis”

- The Three Bell PCBR-I System Kit sells for $1445. (Same as above but 230vac power input).

and linkage including a

Double Solenoid option for the Large or “DeProfundis”

- The Three Bell PCBR Plus System Kit sells for $1595.

Since the goal of the Church

Bell Ministry is to ring God’s Bells, all models have a ten year warrantee.

Specify bell size(s) on the order form

as 15” or smaller which uses the “10 Pounder”. Larger bells (the one finger test)

use the “20 Pounder” Solenoid. Very large bells (the two finger test) use

the “40 Pounder” Solenoid.

See the application note below about

solenoid selection for installation.

How to Order

To start your

Church Bell Ministry, order the Programmable Church Bell Ringer System

Kit.

Please mail a check or money order to

the above address made out to: Church Bell Ministry

for $715* for the Standard PCBR Kit

for $745*** for the PCBR-I Kit

(International – operates on 230vac)

for $1415* for the Standard Three Bell PCBR

Kit

for

$1445*** for the Three

* shipping is included in above prices. Please supply ship to info.

*** USPS International Priority Mail

not included (typically $56 to $80 extra)

For

international orders please use

Specify which PCBR Kit, bell size(s),

optional PVC Solenoid Cover(s) using the order form below.

Since most

church’s do not have credit card accounts, we are sorry but we cannot process

them.

If you are

anxious about mailing a check (your church’s money) to an unknown company for

something that must be

installed or assembled, please be

assured that your complete satisfaction is our promise. This ministry’s goal is to regularly ring our church bells to glorify

God, not to make financial gain.

Feedback from our customer’s delight is our profit!

Here’s what

customers are saying about the Church Bell Ministry:

Ray from

Jim from

Julie from

Ohio, “I found

to do for the

price he was asking.”

Bobby from California, “The Bell is a 24 inch, cast Iron bell that

weighs about 140-160 pounds. It actually

is a

School Bell, but it sounds

great. It's not too loud and just loud

enough. This project came out really

good.”

NOT made in China! Each PCBR Plus Kit and PCBR Kit is

manufactured in Jonesborough Tennessee, USA!

The Church Bell

Ministry has PCBR Kits installed in the

The Church Bell Ministry is the only

Bell Automation Equipment Supplier to provide ‘on line’ pricing. That says a lot!

Use this easy Order Form

to

mail your order.

Click Here

There is no

need for a Capital Campaign to get your bell ringing again!

Great idea for: a Memorial, a Youth Group Project, a

Homecoming event,

a

Centennial Celebration, or other Special Celebration

Get

your group together and see if your church community

doesn’t need to give GOD a little extra attention.

Bring back to your community an American

tradition and Give GOD the Glory!

The Church Bell

Ministry is your supplier for DYI Church Bell Automation Equipment!

Be

sure to listen to some of the mp3 files below demonstrating these bell’s

natural sound!!

Here is the way the Programmable Church Bell Ringer Kit

installs into a church!!

Step 1: Strap down the

tilted bell with Clapper hanging 1” from side of bell. Step 3: If the clapper

does not have a Protrusion, drill, tap & mount standoff. Step 2: Construct a Subframe to the bell’s Main Frame 2“ below free hanging clapper.

Step 5: Mount the PCBR Box and Manual Ring PB and connect

cable from Solenoid. Step 4: Install

Solenoid and connect Plunger linkage to the clapper bottom. Step 6: Program the

PCBR for your Ring Times and enable the TOD chime. Enjoy!

Free

Installation Advisement Available: Send

an email to davessmith@embarqmail.com

with an attached digital picture (*.jpg)

of your bell. We will review and respond

with recommendations.

BELL APPLICATION NOTES

Bell installations are as various as the

creativity of the mind of the installer.

Here are some examples that show

various methods of building the subframe,

positioning the bell and connecting the solenoid linkage to the clapper.

This bell is

installed in the church sign which is located on the side of the roadway. The PCBR Box is installed inside the church

and the solenoid

cable is buried

in plastic conduit. The solenoid wire is

snaked down behind the wallboard and exits the building through a hole drilled

through the brick.

A small junction

box secured to the brick provides a clean transition into the conduit

A man stopped by when I was working on

this bell and asked why it was tilted. I

explained about

the 1“ clapper travel etc…………Then

I s

Some customers did not want to

tilt their bell. The clapper can be

preloaded using a pair of hard rubber

stops that cradle the relaxed clapper

appropriately for the 1” solenoid travel.

This obviously reduces

the strike force because the

effects of gravity. To offset gravity,

two springs can be installed from the

clapper linkage to the solenoid

frame that restore the strike force of the of the PCBR system.

Click on the link for a mechanical

(top view) sketch of the preloaded clapper installation! No Tilt

The PCBR Kits do not normally

include bumpers, so indicate on the order form that you require them.

The tilt mechanism on

this bell installation takes full advantage of the original flange that

connected to the rope lever when the bell was

installed in the

tower. A steel plate, with a “U” shaped

cutout to allow it to fit around the bell shaft, provides strong connectivity

to the

angle adjuster plate. As seen in the picture above, it is hardly

noticeable. Nice for a bell on display.

Most bigger bells have

a spring damper that repels the clapper from the side of the bell except for

the impact strike. This damper

can interfere with the

clapper’s path and reduce the force of the solenoid when striking the bell. It can be shifted out of the way

by inserting a washer

or shim under one side. The top nut will

need to be loosened to insert this shim then retightened.

If this is not

possible, see below.

The spring damper

on this beautiful bell in Wellington, Ohio is spread using two pieces of steel

rod threaded on one end and a

threaded

coupling. The required amount of

separation to achieve clearance is actually quite small. Two pieces of 3/8” threaded

rod cut to the

appropriate length with a hack saw and the hex threaded coupler included with

the PCBR Kit, lock nuts and

Loctite/Gorilla

Glue does the job very nicely. No machine shop effort required! Jim, thanks for the nice picture!

Very large bells

with clapper weight exceeding 8 pounds can use interconnect linkage in a tandem

solenoid pair which will double

the strike force. The solenoids are wired in parallel so they

will activate simultaneously. The drive

circuitry of the PCBR box will

easily handle two

solenoids, but the fuse value will have to be increased due to the change in

load current.

The easiest way to

determine one solenoid or double solenoid is to ring the bell when tilted with

your finger(s). If one finger pulls

the clapper into the

bell easily – then order a single solenoid.

If the mass of the clapper requires two fingers to pull the clapper

against the side

of the bell – then a double solenoid is recommended. As expected, the clapper shown in this picture

took two

fingers. This bell rings at the

The PCBR Kit can be

installed without tilting the bell.

Rubber bumpers “catch” the clapper when the solenoid is not active.

Note the two

springs installed to offset the pull of gravity. Their force is determined using a force gauge

or a simple fish scale.

Connect the scale’s hook to

the bottom of the clapper and pull the clapper to the side of the bell. The spring force is one half

of the measurement

(two springs). Select the spring with a

force just less than ˝ to assure the clapper, when relaxed, will fall

away from the side

of the bell. Note the reflection of the

bell installed at

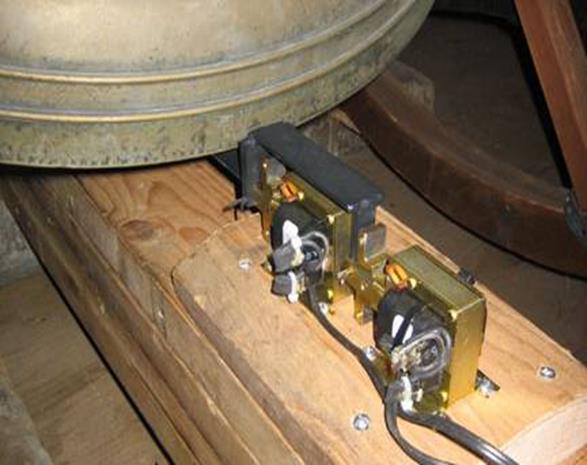

This “40 Pounder” is installed on a

Profundus bell that was cast in 1883. It

is part of the Three Bell Tower of Saint Boniface

Catholic Church in

Brunswick, MO. The 3 Bell PCBR Plus Kit

provided a complete tower ringer system replacement for $1595.

Thanks for the

nice picture, Alan!

This bell

installed in the First Presbyterian Church in Daytona Beach is back in service

for the Lord using a PCBR Plus Kit

with a “40

Pounder”. Stuart is using a steel frame for mounting the solenoids minimizes

any tower resonance that is possible

when the

solenoids pulse. The final touch for

this installation is a good coat of polyurethane on the solenoids, linkage and

metal framework

to protect from the salt air. Jim,

thanks, we always enjoy pictures.

A bell enthusiast at this Catholic Church

rebuilt the bell hammer solenoids and replaced the rectifiers from the original

bell

automation

system. He used the PCBR controller as a

cost effective replacement. The ring

patterns for the

Bell Tower include:

1) Large Bell –

Funeral Toll Ring or 1 strike every 10 seconds for 5 minutes initiated with

manual pushbutton

2) Middle Bell – Angelus

Ring or three

strikes, pause, three strikes, pause, three strikes, pause, nine strikes and

rings at

12 noon and 6 PM

3) Small Bell – Call

to Mass

A Time of Day Chime

can be selected for any one of the three bells as desired

Joe, thanks for the

picture.

Some of the most

beautiful bell towers can be found in the most obscure places. This one is located in Limestone Tennesse.

Where??? You see what I mean. The bell in this tower is shown above

in steps two and three. It required the

clapper

standoff. Cast iron, the usual clapper material,

actually drills and taps quite easily.

Loctite or Gorilla Glue on all machine

threads is an

installation requirement!

These audio clips will demonstrate some

of the PCBR timing settings.

Click Here for Audio Clip of a

Click Here for Audio Clip of a

This bell is suspended from two angle iron struts that bolt to

the overhang frame of the church’s drive thru. This beauty has a rich sound that sounds

like BRASS. Being located at the

church’s main entrance, it demands immediate attention, even when not

ringing.

Click Here for Audio Clip of a

Most churches today are well insulated to minimize energy

usage. This also keeps the sound of

the bell outside too. Uhg! This church installed a microphone about

eight feet from the bell in their steeple and ran it thru their PA system

soundboard. The bell sounds natural

and true inside the church now too!

Click Here for Audio Clip of a

Click Here for Audio Clip of a

This bell is positioned using a coated steel cable fastened to

the bell frame, then extended over the cap nut at the top of the

cradle. A turnbuckle installed in

the left side provides tilt adjustment.

This is a very simple and effective tilt mounting method. The solenoid mounts to a wooden baseplate attached to each

side of the bell frame.

This bell served its

community in both school and church.

Note that the solenoid installation angle is aligned to match the

clapper

swing instead of

perpendicular. The main item is smooth

solenoid plunger travel! If I were over

a hundred years old, my frame would

be twisted just a little too.

It sure doesn’t affect its sound. Listen to the YouTube video clip of the bells

recent rededication. It doesn’t

get much better than this! Note the picture insets. Thanks, Steve

The Women’s Guild at this historic church decided to see what

it would take to get their bell ringing again. The bell manufacturer quoted

$9600 to automate it. A concerned

member who was an engineer found the PCBR Kit on the web and decided to

prototype the installation with it before spending the $9600. When the PCBR Kit was installed, the bell

sounded so wonderful, the high dollar option was deemed a dead issue. The

PCBR Kit is $695. Click Here for Audio Clip of a

This bell is positioned using a 1 inch steel strap fastened to

the cap nut at the top of the cradle then to the rear of wooden bell

mounting frame. When the bell is

positioned correctly, the rear mounting hole is match drilled for a lag

bolt into the wood frame . The solenoid mounts on the wooden frame members. Don’t forget the Loctite or Gorilla Glue on all machine

threads. Click Here for Audio Clip of a

Click Here for Audio Clip of a

This bell is also positioned using a 1 inch steel strap fastened

to the cap nut at the top of the cradle but then up to the top rear of the metal bell mounting frame. The solenoid is mounted to an added wooden subframe that

attaches to the original metal frame. Outdoor bells require a rain cover over the solenoid. Click Here for Audio Clip of a

Click Here for Audio Clip of a

This clapper did not have a

rope attachment extension and required installing the hex extension. A 5/16 – 18 thread was drilled and tapped

at the very bottom of the

clapper. Most clappers are made of cast

iron and drill and tap very nicely. Note

the solenoid linkage and return

spring. This simple setup has been demonstrated to go

for several hundred thousand rings.

A typical

bell tower could have access to the bell by means of a ladder of wooden straps

going STRAIGHT UP. This could be a

little

intimidating. One trip up with an

extension cord or rope used to get the user manual, tools, 2x4s and kit parts

to the bell with a helper

down

below to attach each payload for the haul up. Including a power driver and

saber saw, it took six drop cycles to get everything

I

needed. Using the extension cord, I had

AC power too. The cord or rope is used

for tool and refuse removal when complete.

Finally,

drop the cord and the climb down is easy knowing a job well done!

A PCBR

Plus Kit was installed in this bell tower in Roan Mountain Methodist Church in

Tennessee.

The Church Bell Ministry is your

supplier for Church Bell Automation Equipment!